Our Services

We at Monochrome Plating are trying to bring innovative ways to help ensure that people have access to the best options with the plating to help avoid any premature damage to their vehicle.

Our Solutions

Whenever a hard, corrosion and wear resistant surface is required, Hard Chromium may provide the solution.

Typical applications include hydraulic piston rods, rams, cylinders, shafts, tools and machined parts.

an effective treatment for a variety of metals

We are trying to ensure that you have access to some of the best solutions for all your plating needs. We have state-of-the-art equipment that will allow you to have precision for a seamless finished product.

Hard Chrome Plating Applications

Hydraulic cylinder rods

There are many plating options when it comes to hydraulic cylinder rods, and we can provide you with the options which match your budget the best.

Swivel bodies

Swivel bodies are a nozzle exposed to the water leading to corrosion; we have a practical solution that will keep the body safe.

splined shafts

A splined due to its motion can face a lot of tearing on both the ends, our experts can allow you to enjoy the right action to help ensure smooth functioning.

FROM OUR BLOG

What Are Ceramic Coatings?

Nano-ceramic coatings can be found in both liquid and solid forms and are not only scratch-resistant they also improve surface hardness and are resistant to bacteria! Is there anything this type of coating can’t do!? While ceramic coatings are well known in the automotive world as a great form of paint protection they can also be utilized in a number of different ways. Check out our list of the many types of ceramic coatings:

Nano-ceramic coatings can be found in both liquid and solid forms and are not only scratch-resistant they also improve surface hardness and are resistant to bacteria! Is there anything this type of coating can’t do!? While ceramic coatings are well known in the automotive world as a great form of paint protection they can also be utilized in a number of different ways. Check out our list of the many types of ceramic coatings:

Types of Ceramic Coatings

Anti-Corrosive: applied to metals to stop the oxidation process Waterproof & Non-Stick: waterproof is often applied to various types of clothing & nonstick to furniture, electrical materials & glass Antibacterial: Suitable for public transport to help help with sanitary issues & the spread of bacteria Thermal-Barrier: very prevalent in the aviation industry & is utilized on metallic surfaces Anti-Graffiti: a great option for the government in their efforts to clean up & prevent graffiti Self-Healing: infused with nano-capsules that aid in the repair of light scratches and is used on automotive paint as a form of paint protection. In the end, ceramic coatings bring to the table a remarkable and highly durable protective coating for a number of different surfaces. The benefits they provide are endless and can help to not only protect a surface or vehicle for that matter but also help to preserve it as well. Having a ceramic coating applied to your vehicle will help keep it looking its best for years to come while also improving & maintaining resale value!

Metal Plating Is Highly Toxic & Dangerous

The Health Risks Associated With Chrome Plating

While chrome plating, cadmium plating, and electroplating are widely used on an array of products & materials, the fact of the matter is the chemicals and metals involved in the different plating processes can be toxic to both the environment and especially to a person’s health. Exploring the process of chrome plating and metal plating a little bit can help us to understand the risks involved when it comes to doing any type of metal plating yourself.

What Chemicals In The Plating Process Are Toxic?

First and foremost Hexavalent Chromium is a type of chromic acid that is widely used in the chrome electroplating process to finish different metals. It is HIGHLY toxic and must be handled with great care and proper safety precautions. In fact, there are a number of health risks that are associated with exposure to Hexavalent Chromium. Many that handle Hexavalent Chromium have been known to suffer from cancer, damage to kidneys, lungs, eyes, skin & lower respiratory symptoms. Hexavalent Chromium is a known carcinogen and also utilizes lead that can be absorbed through the skin causing lead toxicity & lead poisoning.

Cadmium is another plating material that is highly toxic & can cause cancer as well as lung and kidney failure. Cyanide is also a chemical utilized with chrome or electroplating and is very toxic to humans and considered a very deadly material. Along with extreme safety and health risks to humans, the materials used in the plating process can be harmful to the environment as well. By-products along with the chemicals being used can cause major water & soil contamination if not treated correctly before waste disposal occurs. It is prudent that any facility practicing any kind of metal plating dispose of their waste products properly & according to the safety and health guidelines set in place.

In the end, we don’t mean to scare you off plating with this article, we just hope to express awareness to the entirety of the chrome plating or electroplating process. Safety and health risks should be taken seriously whenever any type of metal plating is attempted. Knowing the proper safety & hazard measures can help to prevent any damage to the environment and also can help to prevent different types of cancer from any exposure you may have as well as organ damage and in severe cases death.

Cadmium – An Industrial Plating Option

What is Cadmium?

There are various metals that can be utilized when it comes to plating, using various different plating methods. Some offer different benefits than others. One metal that is used for various purposes is Cadmium. Cadmium is a by-product of the production of zinc. Cadmium is highly toxic and is not meant to coat any surface that is in direct contact with food. In fact, Cadmium plating is mostly used in Aerospace, transportation, by the Marines, for consumer electronics, construction & manufacturing. It offers superior protection for both brackish & aquatic applications due to it being highly resistant to corrosion.

What Is Cadmium Plating?

Cadmium Plating was first recognized as a form of protective coating in the 1920s. It is often compared to Zinc Plating in that it is similar. Cadmium plating can be applied with many different plating methods that include electroplating, mechanical cadmium plating, or ion and vacuum deposition. So what is it exactly that sets cadmium apart from other coating materials? Cadmium plating has a number of different properties that set it apart from other types of metal plating which include:

Cadmium Plating was first recognized as a form of protective coating in the 1920s. It is often compared to Zinc Plating in that it is similar. Cadmium plating can be applied with many different plating methods that include electroplating, mechanical cadmium plating, or ion and vacuum deposition. So what is it exactly that sets cadmium apart from other coating materials? Cadmium plating has a number of different properties that set it apart from other types of metal plating which include:

- Highly Resistant To Salt Water Corrosion

- Provides An Exceptional Bonding Surface for Adhesives

- Acts As A Great Electricity Conductor

- High Level Of Solderability

- Naturally Resistant To Both Mold & Bacteria

- Can Easily Be Applied In A Thin, Lightweight Layer

- Easily Coats Complex Shapes & Hard To Reach Contours

Also when compared with zinc, Cadmium retains its original appearance longer and is superior to zinc in marine and industrial environments. Because of Cadmium’s lubricity, it is also preferred for moving parts, as well as parts that are made out of cast iron. It is a soft white metal that, when plated onto steel, cast iron, malleable iron, copper, and powdered metal, functions as a “sacrificial coating,” corroding before the substrate material. It is extremely important that you keep in mind that Cadmium is extremely toxic and can hurt the surrounding environment and those living within it if not disposed of correctly.

Utilizing Different Metal Coatings For Different Finishes

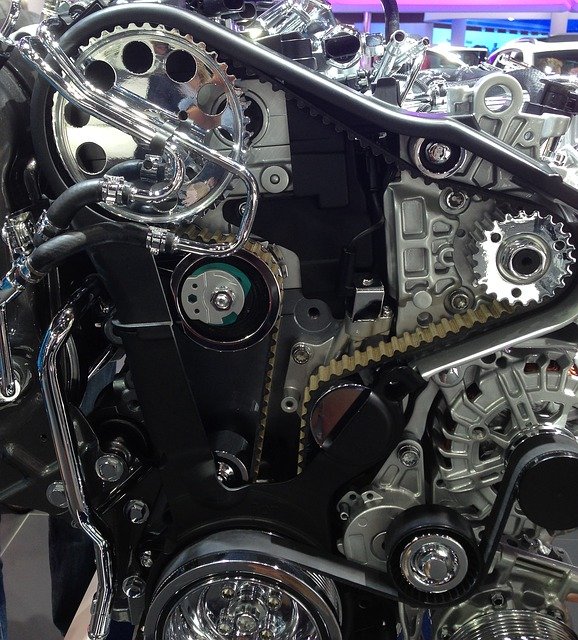

Metal Finishing or coating can be done on various objects for various reasons. One such reason is to coat engine parts both for performance & aesthetic purposes. It is very important that before having any engine part coated you make sure the intended coating is not only the right coating for that part but also safe as well. In fact, Jim with JnJ Auto Service points out that when chrome plating a head gasket or any other engine part that is designed to dissipate heat, the plating can reduce the amount of heat that can be dissipated or released from that engine part. In some cases, heat loss is actually reduced which can cause bigger problems not only for that engine part but for the entire engine of your vehicle. However, it is important to note that when an engine part is coated correctly it can help to add lubricity, corrosion protection, and heat management while also enhancing cosmetic aesthetics.

Different Coating Material For Different Purposes

Dry Film Lubricants – This type of coating contains ingredients like molybdenum disulfide and Teflon that help to add surface lubricity while protecting against friction. This type of coating is most commonly used on piston skirts, engine bearings, intake & exhaust valve stems.

Oil Shedding Coats – This coating contains high levels of PTEE also known as Teflon as well as similar polymers that are great at shedding or repelling oil. This type of coating can improve cooling and oil return to the pump.

Thermal Barriers – These coatings contain high levels of ceramic ingredients and are very poor heat conductors, but are great at reflecting heat. This coating is generally used on the inside/outside of an exhaust manifold.

Thermal Dispersants – This type of coating is great for the inside/outside of oil pans and can also transfer heat more efficiently than bare or painted metal

Generally, if you are looking to have any of your vehicle’s engine parts coated with any type of substance make sure to do your research first and that you utilize the services of a reputable metal coating & finishing professional. It is also a great idea to speak with a trusted mechanic about the coating you are looking into. A certified and honest mechanic can lend great insight and knowledge into what will be best for your vehicle engine’s overall health & longevity.

What Is Metal Finishing?

Metal finishing is the process of changing the surface of an object while also improving its durability and appearance. There are many different types of metal finishing that exist and include techniques such as, electroplating, electroless plating, anodizing, HVOF, vapor deposition, nitriding, and more! Metal finishing applications can also be categorized in terms of residential use, industrial use, commercial use, and military use. Metal finishing is used to coat any metal such as steel, aluminum, non-metallic surfaces, and titanium.

One of the main reasons other than for appearance purposes, that metal finishing is used is to help increase the strength and durability of an object while also improving overall wear & tear, and offering corrosion resistance. Depending on the field it is used in metal finishing can be utilized to coat engine parts, machinery in manufacturing plants, and even faucets and fixtures throughout your home.

In our last article, we discussed one of the most common forms of metal finishing, electroplating. Another common metal finishing technique utilized by many is electroless plating. Although it is very similar to that of electroplating it differs in the fact that it involves liquid baths & ions. It also offers a much slower deposition rate than that of electroplating. Electroless plating as a type of metal finishing is often used on such metals as copper and nickel.

The 5 Most Common Types of Metal Finishing

Now that we have discussed different processes and just what exactly metal finishing entails it is important to also acknowledge the 5 most common types of metal finishing. While the type of finish you choose greatly depends on the metal you are using, the most common finishes are:

Brushed: Creates a matte-like finish that looks as though it has been applied by a brush, leaving brush strokes.

Satin: Similar to a brushed finish, but generally promotes a smooth even finish with no brush strokes

Polished: This offers a reflective mirror-like finish

Antiqued: Made to look aged and weathered, this finish creates a surface roughness by darkening and adding tarnish

Hammered: Adds surface texture to the piece at hand by incorporating an abundance of small indents into the surface of the object.

What Is Electroplating?

When it comes to plating or coating metal there are different plating techniques that can be utilized. One of the most common techniques that are utilized is Electroplating. What is electroplating?

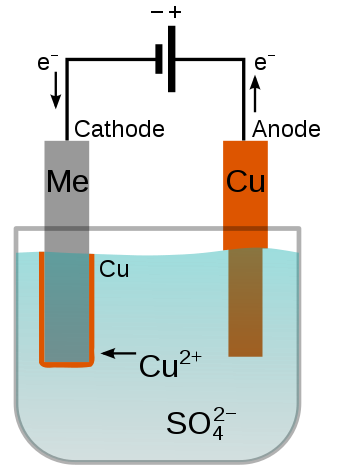

Electroplating is also known as electrodeposition is a process that involves depositing material onto different surfaces with an electric current. Thin pieces of metal are deposited on the surface or substrate of the object. By utilizing the electroplating process you are able to change the physical properties of the object at hand while increasing its wear resistance, adding corrosion protection, enhancing the aesthetic appeal, and increasing thickness. Electroplating is a centuries-old coating process that began as early as the 18th century. It was formalized by Brugnatelli in the first half of the 19th century. Slowly it was adopted by many and moved across Europe continuing on through the Industrial Revolution and both World Wars.

The process of electroplating utilizes an electric current to dissolve metal while working with 4 primary components.

Anode: this is the positively charged electrode in metal that will form the plating.

Cathode: This is the part of the object that needs to be plated and is also known as the substrate while acting as a negatively charged electrode.

Solution: Electro depositing action that must take place in an electrolytic solution. The solution contains one or more salts including copper sulfate which helps to facilitate the flow of electricity

Power Source: This is how the electric current is added to the circuit or electroplating process. The current then goes straight to the anode

Electroplating is a process that can be broke down and simplified by understanding the 4 main components of the process. It is important to note that while it may seem like a simple enough process, electrodeposition/electroplating should always be done by an experienced professional!

Chrome Vinyl Wraps & Chrome-Delete

Chrome plating or finishing can be utilized in many different industries on many different products and materials. One of the most common uses for chrome these days is in the automotive customization industry. That’s right, chrome vinyl wraps for your vehicle are one of the hottest trends allowing you to customize the aesthetics of your car, truck, SUV, trailer, motorcycle, etc. It can be utilized on certain parts or areas of the vehicle including the rims on your tires. And when professionally installed a chrome wrap can last for up to 5 years. Want to know another great aspect of a chrome vinyl wrap for your vehicle? It doesn’t alter or harm the original paint color of your vehicle and it can act as a protective shield. While many people like the look of chrome wrap because it lends a flashier stand-out appearance to their vehicle some are on the other side of the spectrum and look to lend a lower profile look to their car.

And while most vehicles utilize decorative chrome plating by default to not only lend a polished sleek look but to add a protective layer on repeatedly used surfaces, think door handles, mirrors, etc. Some vehicle owners may look to hide or delete chrome accents to personalize their vehicles. So what does deleting or covering the chrome on your vehicle look like?

And while most vehicles utilize decorative chrome plating by default to not only lend a polished sleek look but to add a protective layer on repeatedly used surfaces, think door handles, mirrors, etc. Some vehicle owners may look to hide or delete chrome accents to personalize their vehicles. So what does deleting or covering the chrome on your vehicle look like?

We spoke with a shop known for the best Bay Area vehicle wraps, SS Customs, about Chrome Delete, a very common automotive customization technique which hides or “deletes” chrome accents from your vehicle. . Chrome delete is basically a process that hides the chrome on your vehicle lending a low profile look while also protecting the chrome underneath it. And the great thing about Chromo Delete is it is 100% removable like that of a vehicle vinyl wrap. This allows you to change the look of your vehicle or showcase your individuality without making any permanent decisions. And because Chrome Delete comes in an array of finishes like gloss, matte, or satin you can really customize the look that you are trying to achieve. Should you be looking to enhance the chrome appearance on your vehicle SS Customs are your guys too! They offer some of the best vehicle vinyl wraps available and have won many awards and acknowledgments from some of the industries leading manufacturers.

Whether you are looking to delete the look of your chrome or simply enhance its appearance one thing holds true to both! Chrome is one of the most important materials when it comes to the manufacturing of any automobile. Whether you choose to enhance it or cover it up, the chrome plating on your vehicle helps to protect important aspects of your car, truck, or SUV!

Hexavalent Chromium vs. Trivalent Chromium

The chrome plating process entails the method of applying a thin layer of chromium onto a substrate of metal or alloy through the electroplating process(the passing of electrical currents between electrodes immersed in a chromic acid bath). Because the chrome plating process involves toxic chemicals that need proper disposing of, it is important that the chrome plating process be handled by an experienced professional. Some of the chemicals utilized in the process are also considered carcinogenic.

There are two different chrome plating process methods, Hexavalent & Trivalent, and both are utilized for different purposes. Read on to find out the difference between the two methods and also some of their disadvantages.

Hexavalent Chromium – is the traditional method of chrome plating and is used for decorative and functional finish purposes. This method is done by submerging substrates into a bath of chromium trioxide and sulfuric acid. It helps with corrosion and wear resistance and is also utilized for aesthetic appeal.

Disadvantages: This type of chrome plating produces a lot of hazardous waste and carcinogens that are extremely bad for humans and the environment. It is extremely important taht the byproducts of this chrome plating process are disposed of properly and that safety is of the utmost importance when working with these chemicals. Car manufacturers are even looking to utilize a different type of chrome finish on cars to help reduce the hazardous waste that this process encourages.

Trivalent Chromium – is also another option when it comes to decorative chrome plating and is often viewed as the eco-friendly method. While many in the decorative coating industry feel that Hexavalent chrome plating is better in terms of results, trivalent plating does offer many of the same benefits, like scratch & wear resistance. This type of plating is also available in a variety of colors and utilizes chromium sulfate or chromium chloride as its main ingredient. This makes the process less toxic but also harder to control.

Disadvantages: This type of chrome-plating is not only harder to control than the alternative option, but the chemicals involved also are more expensive. This makes it the chrome plating process cost-competitive with many other plating methods.

All in all chrome plating should be left to the professionals no matter what process of plating you choose. Properly handling, mixing, exposure, and disposal of chemicals is of utmost importance not only to you as an individual but also to the safety and health of the environment.

Hard Chrome Plating Vs. Decorative Chrome Plating

There are various methods through which we can avoid rust, and make objects like plastic, and metal more decorative. Chrome plating is one such example. It is a technique through which you electroplate a thin layer of chromium on plastic and metal substances. This makes the object corrosion resistant. It also makes the object more decorative, pleasing, durable, and increases the hardness of the surface of the object.

Uses:

Chrome plating is done by experts for different objects. It has a variety of uses. It is mostly done for commercial purposes like motorbikes, and car chrome. You can find a lot of chrome services that will cater to your requirements. If done on a motorbike, it will enhance the exterior parts hence makes the machine parts more durable.

Types:

The main types of Chrome plating are two. Decorative Chrome plating, and Hard Chrome Plating. They have different uses, and can’t take the place of one another. Decorative Chrome plating is used for decorating door handles, tap-ware, architectural fittings, racks, wheels, ad furniture. The base for plating of this kind includes aluminium, copper, alloys, and zinc. It is done to make the object look more attractive.

Hard chrome plating:

Objects wear down over time and become vulnerable to rust. Hard chrome plating is one such technique that comes to your rescue., It is done to increase the durability of the substance. It is used in industrial, and engineering products. In this, a thick layer is applied to the object. You can also find it on motorbikes, and machine parts of the car, and bikes. This increases the durability of the object and saves it from the corrosion by increasing the protective layer.

Which one is better:

Both types have their use, and you can’t say which one is better. It depends on your requirement. If you need Hard chrome plating, Decorative can’t do your work. The former is meant for industrial purposes, but the latter is used for visual purposes. It may not necessarily increase the durability a lot, but hard chrome plating is quite the opposite. Decorative increase the visual appearance of the object, and makes it better in look. However, hard chrome plating is solely meant for increasing durability.

Conclusion:

If you are confused about what to choose, then first you have to make sure that you understand your requirements. See what is needed the most; whether you want the decorative purpose or the durability. You will be able to decide in no time once you know what you want. Corrosion is no good for any object, and with Hard chrome plating, you not only can make the object look good but make sure that it is corrosion-resistant. This way the object is protected, and durable.